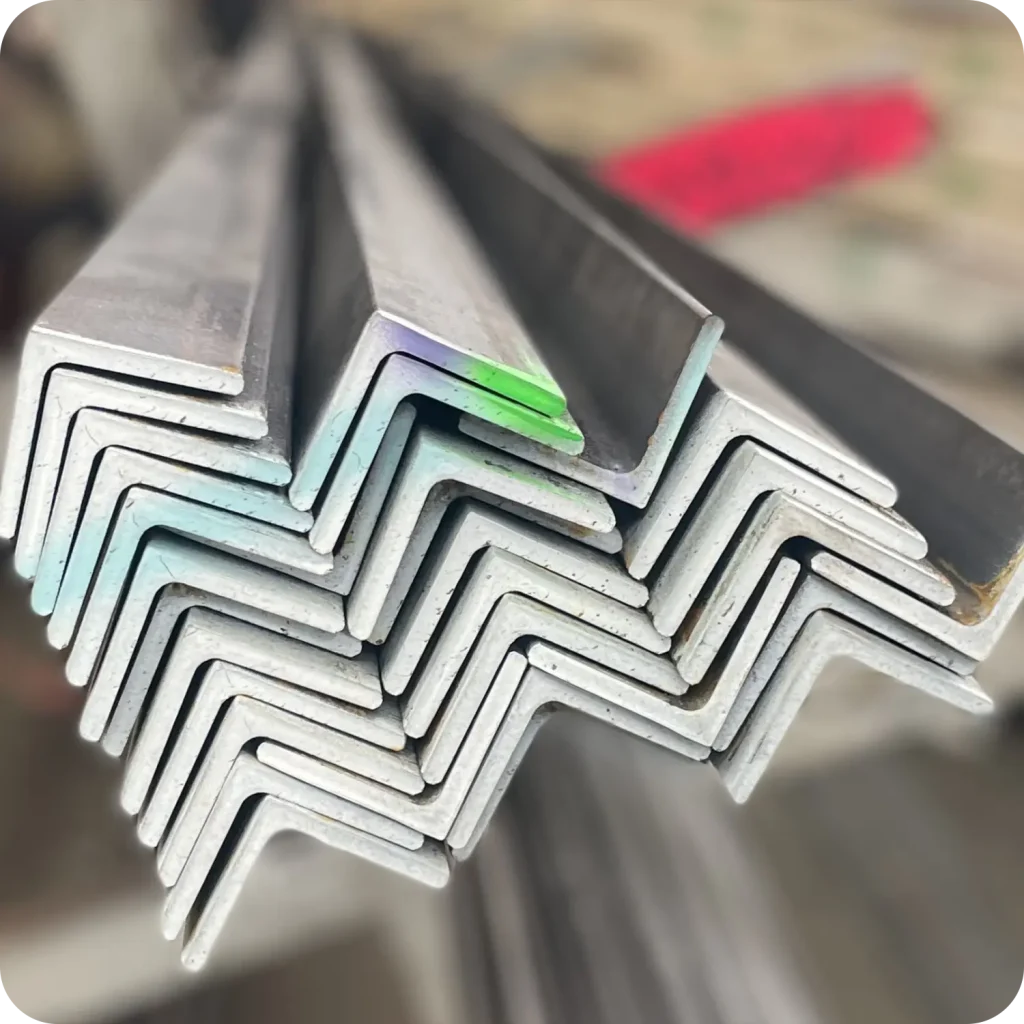

Steel Channel (U-Profile – UPE / UNP) – European Standard Steel Channels for Structural Support

Steel Channel (U-Profile – UPE / UNP), also known as U-channels or C-channels, are hot-rolled steel profiles with a U-shaped cross-section. Manufactured according to European standards (EN 10279 / EN 10025), these channels are widely used in construction, mechanical structures, and industrial fabrication due to their strength, stability, and versatility.

Key Characteristics of Steel Channel (U-Profile – UPE / UNP)

U-Shaped Cross-Section

UPN channels feature a profile with two parallel flanges connected by a central web, forming a “U” shape that offers strong load-bearing capacity and easy integration with other structural components.

Tapered Flanges

The flanges of UPN channels are slightly tapered, which helps improve strength and stiffness under compressive or bending loads.

European Standard Design

Produced according to EN 10279 and EN 10025, UPN channels ensure consistent quality, dimensional accuracy, and reliable mechanical properties.

High Strength and Stability

These channels are designed to resist torsion, bending, and compression, making them ideal for horizontal and vertical load applications.

Ease of Fabrication

UPN channels can be easily drilled, cut, and welded, making them suitable for a wide range of custom construction and industrial uses.

Common Applications of Steel Channel (U-Profile – UPE / UNP)

UPN steel channels are widely used in structural and industrial applications such as:

Framing Systems

Used for secondary framing in metal buildings and steel structures.

Support Beams and Purlins

Provide reliable support in roof structures, mezzanines, and platforms.

Machinery and Equipment Frames

Ideal for constructing base frames and supports for machines and equipment.

Bracing and Reinforcement

Used in conjunction with other steel profiles to increase structural rigidity.

Civil and Industrial Projects

Common in bridges, supports, rail systems, and general steel fabrication.

UPN Channel Size Chart (Dimensions in mm)

| Size | Height (h) | Flange Width (b) | Web Thickness (tw) | Weight (kg/m) |

|---|---|---|---|---|

| UPN 80 | 80 | 45 | 8 | 8.64 |

| UPN 100 | 100 | 50 | 8.5 | 10.6 |

| UPN 120 | 120 | 55 | 9 | 13.4 |

| UPN 140 | 140 | 60 | 10 | 16.7 |

| UPN 160 | 160 | 65 | 10.5 | 20 |

| UPN 180 | 180 | 70 | 11 | 23.5 |

| UPN 200 | 200 | 75 | 11.5 | 27.4 |

| UPN 220 | 220 | 80 | 12 | 31.5 |

| UPN 240 | 240 | 85 | 12.5 | 36 |

| UPN 260 | 260 | 90 | 13 | 40.5 |

| UPN 280 | 280 | 95 | 13.5 | 45.4 |

| UPN 300 | 300 | 100 | 14 | 50.5 |

Other sizes and grades (S235, S275, S355) are available on request to suit your project needs.

Why Choose UPN Channels

UPN channels provide an excellent balance of strength, versatility, and ease of installation. Whether used as purlins, machine supports, or part of a structural frame, they offer dependable performance in demanding environments. Their compliance with European standards ensures reliability for construction, manufacturing, and infrastructure applications.